Mechanical Recycling of Plastics Market Size | Companies Analysis 2025-2034

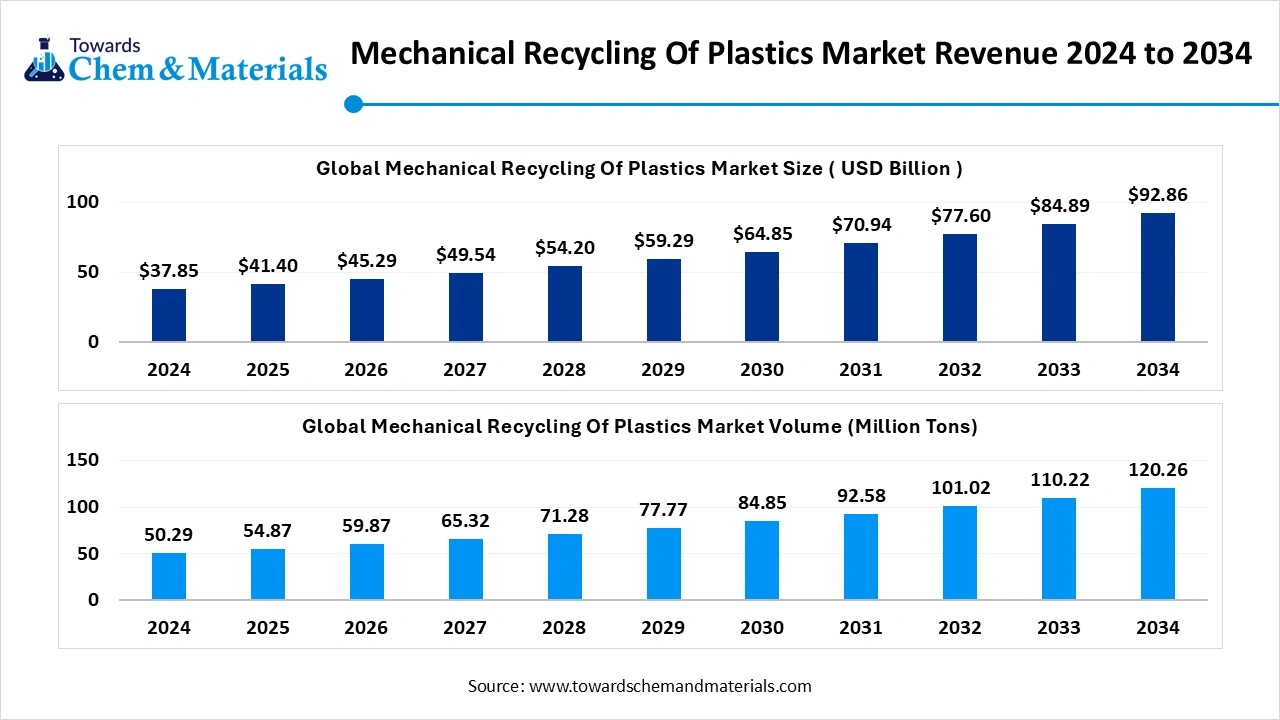

The global Mechanical Recycling of Plastics market size is calculated at USD 41.40 billion in 2025 and is expected to surpass around USD 92.86 billion by 2034, growing at a compound annual growth rate (CAGR) of 9.39% over the forecast period 2025 to 2034. Top Key companies profiled: BASF; TOMRA Systems ASA; Trinseo; TotalEnergies; Eastman Chemical Company; Dow; Coperion GmbH; Covestro AG; LG Chem; LyondellBasell Industries Holdings B.V

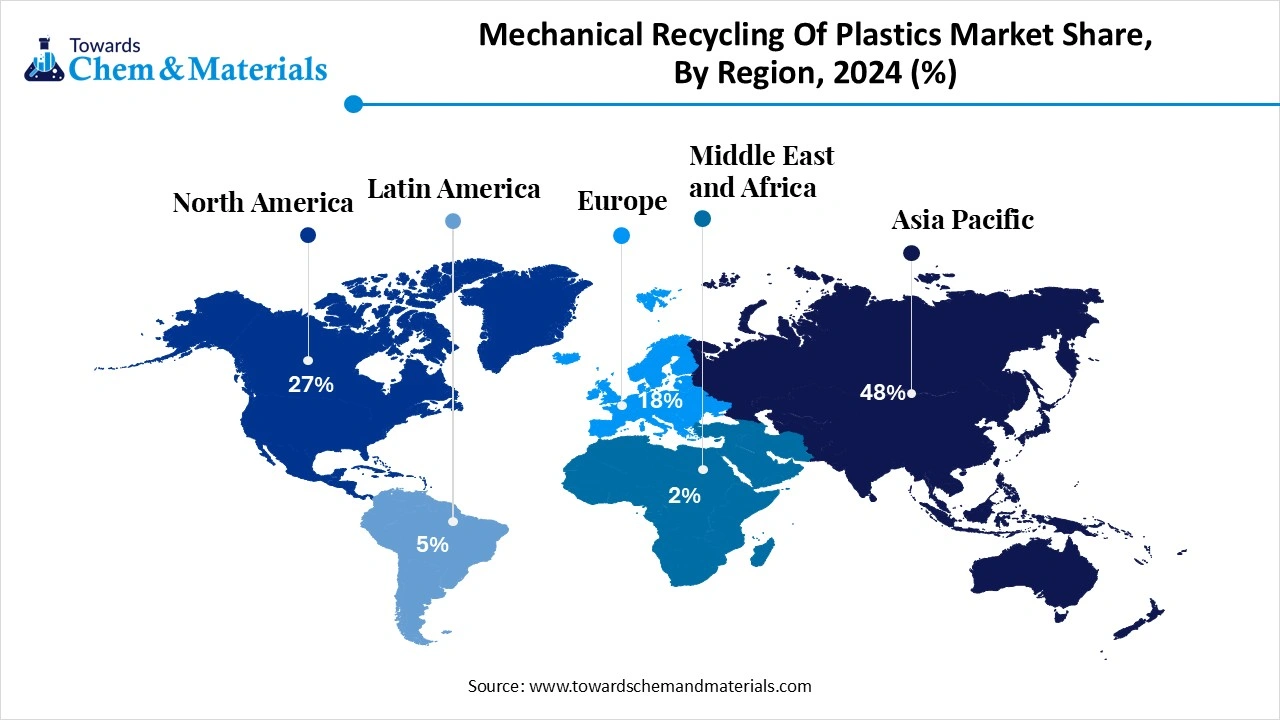

Ottawa, Nov. 05, 2025 (GLOBE NEWSWIRE) -- The global mechanical recycling of plastics market size was valued at USD 37.85 billion in 2024 and is anticipated to reach around USD 92.86 billion by 2034, growing at a compound annual growth rate (CAGR) of 9.39% over the forecast period from 2025 to 2034. Asia Pacific dominated the mechanical recycling of plastics market with a market share of 48% in 2024.A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/download-sample/5896

According to Towards Chemical and Materials, the global mechanical recycling of plastics market is experiencing rapid growth, with volumes expected to increase from 54.87 million tons in 2025 to 120.26 million tons by 2034, representing a robust CAGR of 9.11% over the forecast period.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

Mechanical Recycling of Plastics Market Report Highlights

- Asia Pacific dominated the market and accounted for the largest revenue share of 48% in 2024.

- By recycling process, the extrusion segment accounted for the largest revenue share of 35% in 2024.

- By source of plastic waste, the post-consumer recycled segment held the largest revenue share of 60% in 2024.

- By polymer type, the polyethylene segment accounted for the largest revenue share of around 32% in 2024.

- By product form, the flakes segment dominated the market with a share of 76% in 2024

- By application, the packaging segment held the largest revenue share of 38% in 2024.

What are the steps of mechanical recycling?

Mechanical recycling is processing plastics waste into secondary raw materials or products without significantly changing the material’s chemical structure. In principle, all types of thermoplastics can be mechanically recycled with little or no impact on quality.

- Collection: Collection of end-of-life plastic products from separate and mixed waste streams

- First sorting: Once plastic waste arrives at the recycling plant, it is sorted. While some sorting may have taken place at the collection stage, further separation by colour or thickness may be necessary.

- Shredding: Plastics need to be shredded into smaller pieces before they can go on for reuse.

- Washing: Washing removes dust and dirt to ensure plastics are clean before they go onto the next stage. This can include removing traces of food, drink or labels.

- Second sorting and control: Plastics are sorted again and controlled before being sent to extrusion.

- Extrusion: Plastics flakes are finally converted into homogenous pellets ready to use in the manufacture of new products

Invest in Premium Global Insights Immediate Delivery Available (Global Deep Dive USD 3900) https://www.towardschemandmaterials.com/checkout/5896

Mechanical Recycling Of Plastics Market Report Scope

| Report Attribute | Details |

| Market size value in 2026 | USD 45.29 Billion |

| Revenue forecast in 2034 | USD 92.86 Billion |

| Growth rate | CAGR of 9.39% from 2025 to 2034 |

| Historical data | 2021 - 2024 |

| Base Year | 2024 |

| Forecast period | 2025 - 2034 |

| Quantitative units | Revenue in USD million/billion, Volume in Kilotons, and CAGR from 2025 to 2034 |

| Segments covered | By Recycling Process, By Source of Plastic Waste, By Polymer Type, By Product Form, By Application, By Region |

| Regional scope | North America; Europe; Asia Pacific; Central & South America; Middle East & Africa |

| Key companies profiled | BASF; TOMRA Systems ASA; Trinseo; TotalEnergies; Eastman Chemical Company; Dow; Coperion GmbH; Covestro AG; LG Chem; LyondellBasell Industries Holdings B.V EREMA Group, Polystar Machinery Co., Ltd., Vecoplan AG, Herbold Meckesheim GmbH, KOWIN Plastic Machinery Co., Ltd., Starlinger & Co. GmbH, B+B Anlagenbau GmbH, ASG Recycling Machinery, Pluto Intero, Archana Extrusion Machinery Mfg., Sorema S.p.A., Doll Plast S.r.l., Plasmac S.r.l., Next Generation Recyclingmaschinen GmbH, Moretto S.p.A. |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

Why Recycling Multi-Layer Plastics is Important?

Modern packaging is built upon materials, which are made of two or more layers of various polymers and usually incorporate such materials as aluminium foil or paper. The issue of multilayer plastic poses a more difficult challenge within the vast problem of plastic waste that the world is facing. The multilayer plastic is designed as a method to provide excellent barrier properties to increase shelf life and food spoilage prevention, which is a paramount requirement in the food-insecure world, especially with chip packets, coffee pouches, and sachets of medicine. Yet, their complexity, as a factor, has always made them non-recyclable by normal mechanical means, pushing billions of tonnes of material into landfill or even worse, it can leak into the environment. Failure to recycle multilayer plastic effectively is a colossal economic and environmental waste that amounts to pollution and directs at the depletion of limited resources. To businesses whose operational objectives and goals are firmly in place in the realm of a circular economy, like Banyan Nation, the multilayer of plastic puzzle is not mere fantasy; it is the future of sustainable management of materials. We should cease to treat these materials as a waste and start treating them as useful feedstock. This paradigm shift needs to be innovative in collection, sorting, and high-tech recycling technology to make sure that all the layers are reclaimed and re-enter the manufacturing supply chain to guarantee the resource efficiency and environment integrity to the following generations.

Major Private Industry Investments for Mechanical Recycling of Plastics:

- Re Sustainability and Recycling Private Limited & Aarti Circularity Limited: These Indian companies announced an initial ₹100 crore joint investment to build advanced infrastructure for plastic recycling.

- LyondellBasell and Shakti Plastic Industries: LyondellBasell partnered with Shakti Plastic Industries to establish what is described as India's largest plastic recycling plant.

- Banyan Nation: This vertically integrated Indian plastic recycling company has a cumulative capacity of 12,000 tonnes and utilizes a data-based platform to track its supply chain.

- Circulate Capital Ocean Fund: This fund, backed by major corporations like PepsiCo and Coca-Cola, represents $106 million in committed capital for investments in plastic recycling in South and Southeast Asia.

What Are the Major Trends in The Mechanical Recycling of Plastics Market?

- There is a growing focus on enhancing sorting, cleaning, and extrusion technologies to improve the quality and consistency of mechanically recycled plastics.

- Corporations and brand owners are increasingly committing to circular economy goals, driving demand for mechanically recycled plastics in packaging, automotive, and durable goods.

- Regulatory frameworks around the world are becoming more stringent on plastic waste management, recycled content targets, and extended producer responsibility, reinforcing market growth.

- Expansion of recycling infrastructure in emerging regions is underway as industrialisation and urbanisation increase plastic waste generation and create new opportunities for medical recycling.

- Shift in consumer and supply chain preference from virgin plastics to recycled materials is driving investment into mechanically recycled polymer feedstock and downstream recycled plastic products.

How Does AI Influence the Growth of the Mechanical Recycling of Plastics Industry in 2025?

AI-enabled systems are significantly improving the sorting and separation processes in mechanical plastic recycling by using machine learning, computer vision, and sensor fusion to identify, classify, and segregate different polymer types and contaminants with high accuracy and speed. By enhancing material purity and reducing contamination, AI is helping make recycled plastics more suitable for high-value applications, thereby boosting demand and supporting industry expansion.

Mechanical Recycling of Plastics Market Growth Factors

Can Smarter Machines Boost Material Quality?

AI-driven robots equipped with computer vision and sensor arrays are increasingly deployed in recycling plants to accurately identify and sort different plastic types and contaminants, which in turn improves the purity of recycled feedstock and supports higher-value recycling. This enhanced sorting efficiency lowers rejection rate and drives confidence among manufacturers that mechanically recycled plastics can meet stricter specifications, thereby expanding demand and market growth.

Are Brands Demanding More Recycled Content?

Large consumer goods and packaging companies are accelerating commitments to use recycled plastics, design packaging for recyclability, and reduce virgin plastic use, which creates a stronger pull-through for mechanically recycled plastics. As brands align with circular economy goals and regulatory pressure mounts, the increased uptake of recycled resin supports the expansion of mechanical recycling infrastructure and market adoption.

Market Opportunity

Could Mixed Waste Streams Become Untapped Feedstock?

With growing initiatives aimed at collecting and processing mixed plastic waste that previously ended up in landfills, the mechanical recycling industry is positioned to convert a broader range of plastic type into reusable materials offering an opportunity for operators to secure new input streams and improve materials flows this opens the door for investments in infrastructure that handle complex plastics and creates value added outputs from what was once considered waste.

Might Flexible Packaging Unlock a New Plastics Recycling Frontier?

As brands pivot towards sustainable packaging and seek materials designed for recyclability, the demand for recycled content in flexible formats is rising, creating a chance for the mechanical recycling sector to adapt and extend into these previously harder-to-recycle streams. Recyclers who can integrate suitable sorting and cleaning for flexible films could access this growing demand and carve out differentiated market positions.

Limitations & Challenges:

- A key limitation of the market is that contamination and mixed polymer waste streams compromise the quality of recycled plastics, making them unsuitable for high-value applications.

- Another limitation is that repeated mechanical recycling degrades polymer properties over time, which restricts the reuse of recycled plastics in demanding sectors and fosters downcycling rather than true circular reuse.

Immediate Delivery Available | Buy This Premium Research Report (Global Deep Dive USD 3900) https://www.towardschemandmaterials.com/checkout/5896

Mechanical Recycling of Plastics Market Segmentation Insights

Recycling Process Insights:

Why Does the Extrusion Process Dominates the Mechanical Recycling of Plastics Market?

The extrusion process segment dominated the market in 2024. Extrusion is widely adopted due to its ability to efficiently convert plastic flakes and pellets into high-quality recycled materials through melting and reshaping. This method supports large-scale operations, minimizes material loss, and allows recyclers to produce uniform recycled polymers suitable for multiple applications. The widespread industrial acceptance of extrusion, combined with continuous improvements in machinery and process control, has positioned it as the core technology driving mechanical recycling efficiency and consistency.

The pelletizing process segment is projected to grow at the fastest rate from 2025 to 2034. Pelletizing offers recyclers enhanced flexibility in creating standardized recycled resins that can easily integrate into manufacturing lines for packaging, construction, and automotive products. Its growing popularity stems from increasing demand for high-quality, reprocess able, recycled pallets that mimic the properties of virgin polymers. As industries focus on sustainable production and circular economy initiatives, palletizing technology is gaining momentum for its ability to improve product consistency, logistics efficiency, and market value.

Source of Plastic Waste Insights:

Why Is Post-Consumer Waste Dominating the Mechanical Recycling of Plastics Market?

The post-consumer plastic waste segment dominated the market in 2024. Rising environmental awareness and policy initiatives promoting household and packaging waste collection have made post-consumer plastics the largest input source for mechanical recycling. The segment benefits from strong recycling infrastructure and brand commitments to using recycled packaging materials. With rapid improvements in sorting, cleaning, and reprocessing, recyclers can now handle larger volumes of consumer waste, transforming it into viable feedstock for diverse applications across packaging, textiles, and durable goods.

The post-industrial plastic waste segment is projected to grow at the fastest rate during the forecast period. This growth is fuelled by manufacturing sectors seeking to minimize waste and recycle production scrap directly at the source. The consistent quality and lower contamination levels of post-industrial plastics make them ideal for high-performance recycled materials. Growing industrial adoption of in-house recycling systems and partnerships with recyclers is accelerating the expansion of this segment, helping companies achieve circularity and reduce disposal costs.

Polymer Type Insights:

Why Is Polyethylene Dominating the Mechanical Recycling of Plastics Market?

The polyethylene (PE) segment dominated the market in 2024. Polyethylene, including both high- and low-density grades, is one of the most widely used polymers globally, especially in packaging, consumer goods, and agricultural films. Its broad availability and recyclability make it a cornerstone of mechanical recycling operations. The established infrastructure for collecting and reprocessing PE waste supports large-scale circular initiatives, while technological advances are enhancing its recycled form, enabling wider applications across packaging and industrial sectors.

The polycarbonate segment is projected to have the highest growth rate over 2025-2034. Growing demand for durable and transparent materials in the automotive, electronics, and construction industries is accelerating the mechanical recycling of polycarbonate. This polymer’s high performance and potential for multiple reprocessing cycles make it attractive for closed-loop recycling initiatives. The industry’s shift toward sustainable, lightweight materials and the development of efficient separation and cleaning technologies are driving the faster adoption of recycled polycarbonate across emerging industrial applications.

Product Form Insights:

Why Are Flakes Dominating the Mechanical Recycling of Plastics Market?

The flakes segment dominated the market in 2024. Recycled flakes serve as the primary intermediate product for mechanical recycling, enabling their direct use in manufacturing new packaging, fibres, and industrial goods. The segment benefits from cost-effective processing, easy storage, and compatibility with extrusion and moulding techniques. With advances in washing and shredding technologies, high-quality flakes with reduced contamination are increasingly produced, reinforcing their dominance in supplying reliable recycled inputs to downstream converters and end-use industry.

The pellets segment is anticipated to grow at the fastest rate during the forecast period. Pellets are favoured for their uniformity, ease of transport, and superior process ability in manufacturing applications. The growing emphasis on closed-loop production systems and consistent material properties has driven demand for pelletized recycled plastics. As recyclers adopt advanced pelletized technologies and automation, they are producing high-grade materials compatible with packaging, automotive, and construction uses, making pellets the preferred choice for large-scale industrial reuse.

Application Insights:

Why Is Packaging Dominating in the Mechanical Recycling of Plastics Market?

The packaging segment dominated the in 2024. Global efforts to reduce single-use plastic waste and brand initiatives to include recycled content in packaging materials have strengthened this segment. Recycled plastics are increasingly utilized in containers, bottles, films, and flexible packaging applications. The packaging industry’s large-scale consumption of polyethylene and polypropylene, combined with sustainability regulations, continues to anchor its leading role in driving the adoption and advancement of mechanical recycling technologies.

The automotive components segment is projected to grow at the fastest rate from 2025 to 2034. Rising demand for lightweight and sustainable materials in vehicle manufacturing is increasing the use of mechanically recycled plastics. Automakers are integrating recycled polymers into dashboards, interior trims, and underbody components to lower emissions and enhance recyclability. The combination of strict environmental regulations, consumer awareness, and innovation in material engineering is fuelling the rapid expansion of this segment, making it a key frontier for mechanical recycling growth.

Regional Insights

Why Is the Asia Pacific Region Dominating the Mechanical Recycling of Plastics Market?

Asia Pacific dominated the market share of 48% in 2024. The Asia Pacific region has become the primary hub for mechanically recycling plastics thanks to its massive volumes of post-consumer waste, strong infrastructure for washing and extrusion, and growing mandates for recycled content in packaging and industrial uses. The established collection networks across countries like India and Southeast Asia, combined with cost-effective mechanical processes, enable large-scale recycling operations that support dominance in the region.

China Mechanical Recycling of Plastics Market Trends

China stands out in the Asia Pacific as a key player driving mechanical recycling with its vast installed capacity and strong policy impetus to reduce plastic waste and boost circularity. With its domestic recycling ecosystem and emphasis on feedstock recovery, China is reinforcing its position as a market leader and influencing the regional dynamics of plastics recycling.

What is the Position of North America in the Mechanical Recycling of Plastics Industry?

The North American region is emerging as the fastest-growing market in mechanical recycling of plastics, driven by escalating corporate sustainability commitments, evolving regulations that encourage recycled content, and an increasing push for closed-loop systems. Enhanced investments in recycling infrastructure, such as sorting, cleaning, and extrusion operations, are enabling better quality output, which expands the range of applications for recycled plastics and supports rapid market expansion.

U.S. Mechanical Recycling of Plastics Market Analysis

The U.S. is a pivotal driver for North America’s accelerating mechanical recycling market, where legislation at the federal and state levels is mandating higher recycled materials usage and stricter waste management standards. Significant upgrades to processing capabilities and partnerships with major brands seeking recycled content feedstocks are strengthening the U.S. position and helping scale more robust mechanical recycling operations across the region.

Europe Mechanical Recycling Of Plastics Market Analysis

Europe mechanical recycling of plastics market dominated globally with the largest revenue share of 18% in 2024.Europe’s stringent regulatory landscape is a major driver for the mechanical recycling of plastics. The European Union's policies, such as the Circular Economy Action Plan and the Single-Use Plastics Directive, are pushing industries to drastically reduce plastic waste and increase recycling rates. These regulations are coupled with aggressive recycling targets, requiring member states to implement robust mechanical recycling systems.

Germany mechanical recycling Of plastics market is driven by the well-established recycling infrastructure and leadership in environmental policies, which are key drivers for the market growth. The country has implemented one of the most advanced waste management systems globally, driven by stringent recycling laws like the Verpackungsgesetz (Packaging Act), which enforces high recycling quotas for plastic packaging. German industries, particularly automotive and packaging, are adopting recycled plastics to meet sustainability targets and reduce reliance on virgin materials.

Top Companies in the Mechanical Recycling of Plastics Market & Their Offerings:

- EREMA Group: They provide a broad range of complete mechanical plastics recycling solutions, from washing and drying to pelletizing, that transform plastic waste into high-quality, reusable pellets for various applications including food-grade and post-consumer uses.

- Polystar Machinery Co., Ltd.: Polystar specializes in user-friendly, high-efficiency, one-step recycling machines that convert flexible plastic film (both post-industrial and post-consumer) and rigid plastic waste into uniform, high-quality pellets for reuse in new products.

- Vecoplan AG: Vecoplan offers advanced shredding and material processing technologies, including dry and wet cleaning systems, that prepare plastic waste into high-quality, extrudable flakes ready for further processing or compounding.

- Herbold Meckesheim GmbH: Herbold is a specialist in manufacturing machines and systems for the size reduction (shredders, granulators, pulverizers), washing, separation, and drying of all types of plastic waste, from clean industrial scrap to heavily contaminated post-consumer materials.

- KOWIN Plastic Machinery Co., Ltd.: Kowin provides various plastic recycling machines, including lines for film and rigid plastics, offering solutions for washing, shredding, and pelletizing to help manufacturers process their waste efficiently.

- Starlinger & Co. GmbH: Starlinger offers pioneering recycling systems, particularly for PET, PP, and PE, that convert post-industrial and post-consumer waste into valuable secondary raw materials, including bottle-to-bottle applications.

- B+B Anlagenbau GmbH: B+B Anlagenbau provides specialized components and systems for plastics recycling, focusing on mechanical processing solutions that can be integrated into full recycling lines.

- ASG Recycling Machinery: ASG offers a range of machinery for the entire process of plastic recycling, including shredding, washing lines, separation, and pelletizing equipment suitable for various types of plastic waste.

- Pluto Intero: Pluto Intero supplies a variety of machinery and solutions for the mechanical recycling of plastics, including components for washing and pelletizing systems.

- Archana Extrusion Machinery Mfg.: This company manufactures extrusion machinery primarily for the plastics industry, which includes pelletizing systems crucial for the final stage of mechanical plastic recycling.

- Sorema S.p.A.: Sorema specializes in designing and manufacturing complete, automated washing lines and recycling plants for post-consumer and post-industrial plastic waste, with a strong focus on PET bottle washing.

- Doll Plast S.r.l.: Doll Plast offers a wide range of recycling solutions including shredders, granulators, washing lines, and dryers for various plastic materials, from film to rigid plastics.

- Plasmac S.r.l.: As part of the EREMA Group, Plasmac focuses on manufacturing high-efficiency recycling machines specifically for in-house (post-industrial) film and production waste, often for inline or off-line application.

- Next Generation Recyclingmaschinen GmbH (NGR): NGR specializes in designing and producing innovative plastic recycling machines that turn industrial and post-consumer waste into high-quality pellets using efficient, energy-saving technology.

-

Moretto S.p.A.: Moretto provides auxiliary equipment for the plastics processing industry, including material handling, drying, and storage systems that are essential components in a comprehensive mechanical recycling setup.

More Insights in Towards Chemical and Materials:

- Asia Pacific Recycled Plastics Market Size | Companies Analysis 2025- 2034

- Recycled Engineering Plastics Market Size and Companies Revenue by 2025- 2034

- Commodity Plastics Market Size & Share, Statistics Report 2025-2034

- U.S. Biodegradable Plastics Market Prices, News, Monitor, Market Analysis & Demand

- U.S. Smart Plastics In Precision Agriculture Market Outlook, In-Depth Analysis & Forecast to 2034

- Biodegradable Plastics Market Price Trend and Forecast in Top 10 Leading Countries Worldwide

- U.S. Recycled Plastics in Green Building Materials Market Size to Worth USD 1,941.65 Million by 2034

- Plastics Market 2025–2034 Analysis and Future Outlook

- U.S. Plastics Market: - Industry News, Resin Pricing & Analysis

- U.S. Recycled Plastics Market: Demand, Production, and Future Projections

- Recycled Plastics Market: Demand, Production, and Future Projections

- Sustainable Plastics Market Size, Share, Trends & Growth Report, 2034

- Circular Plastics Market - Current Status and Future Innovations

- U.S. Transparent Plastics Market: Demand, Production, and Future Projections

- Recycled Plastics In Green Building Materials Market: Demand, Production, and Future Projections

- Transparent Plastics Market: Demand, Production, and Future Projections

- Europe Bioplastics Market - Current Status and Future Innovations

- Plastics Extruded Market : Demand, Production, and Future Projections

- Asia Pacific Bioplastics Market - Current Status and Future Innovations

- Bioplastics Market: Demand, Production, and Future Projections

- Engineering Plastics Market Price Trend and Forecast in Top 10 Leading Countries Worldwide

- Europe Plastics Market Size and Companies Revenue by 2025- 2034

- Recycled Thermoplastics Market - Current Status and Future Innovations

- Thermoplastics In Construction Films Market - Current Status and Future Innovations

- U.S. Metal Recycling Market Size & Share, Statistics Report 2025-2034

- Metal Recycling Market: Demand, Production, and Future Projections

- Microplastic Recycling Market - Current Status and Future Innovations

- Mechanical & Chemical Recycling of Polyethylene Market: Demand, Production, and Future Projections

Mechanical Recycling of Plastics Market Top Key Companies:

- EREMA Group

- Polystar Machinery Co., Ltd.

- Vecoplan AG

- Herbold Meckesheim GmbH

- KOWIN Plastic Machinery Co., Ltd.

- Starlinger & Co. GmbH

- B+B Anlagenbau GmbH

- ASG Recycling Machinery

- Pluto Intero

- Archana Extrusion Machinery Mfg.

- Sorema S.p.A.

- Doll Plast S.r.l.

- Plasmac S.r.l.

- Next Generation Recyclingmaschinen GmbH

- Moretto S.p.A.

Recent Developments

- In March 2025, Eni’s chemical division, Versalis, opened a new plant in Italy aimed at producing plastics from mechanically recycled raw materials. This launch signales a shift in major petrochemical players toward circular economy strategies and closing the loop on packaging and construction feedstocks.

- In September 2025, ExxonMobil announced it would pause its European plastic recycling investment amid uncertainty over draft EU rules on recycled content, underscoring how evolving regulation is already influencing capital deployment I plastics recycling infrastructure. ExxonMobil put $118million chemical recycling investment in Europe.

Mechanical Recycling of Plastics Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2034. For this study, Towards Chemical and Materials has segmented the global Mechanical Recycling of Plastics Market

By Recycling Process

- Shredding

- Washing

- Extrusion

- Pelletizing

By Source of Plastic Waste

- Post-Consumer Recycled (PCR)

- Post-Industrial Recycled (PIR)

By Polymer Type

- Polyethylene (PE)

- Low-Density (LDPE)

- High-Density (HDPE)

- Linear Low-Density (LLDPE)

- Polypropylene (PP)

- Polyethylene Terephthalate (PET)

- Polystyrene (PS)

- Polyvinyl Chloride (PVC)

- Polycarbonate (PC)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyamide (PA)

- Polyoxymethylene (POM)

By Product Form

- Pellets

- Flakes

- Sheets

- Films

- Granules

By Application

- Packaging

- Rigid Packaging

- Flexible Packaging

- Automotive Components

- Construction Materials

- Consumer Goods

- Textiles

- Agriculture

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report (Global Deep Dive USD 3900) https://www.towardschemandmaterials.com/checkout/5896

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.